How customizable are modular cold storage buildings for varying temperature needs?

Admin

August 29, 2025

August 29, 2025

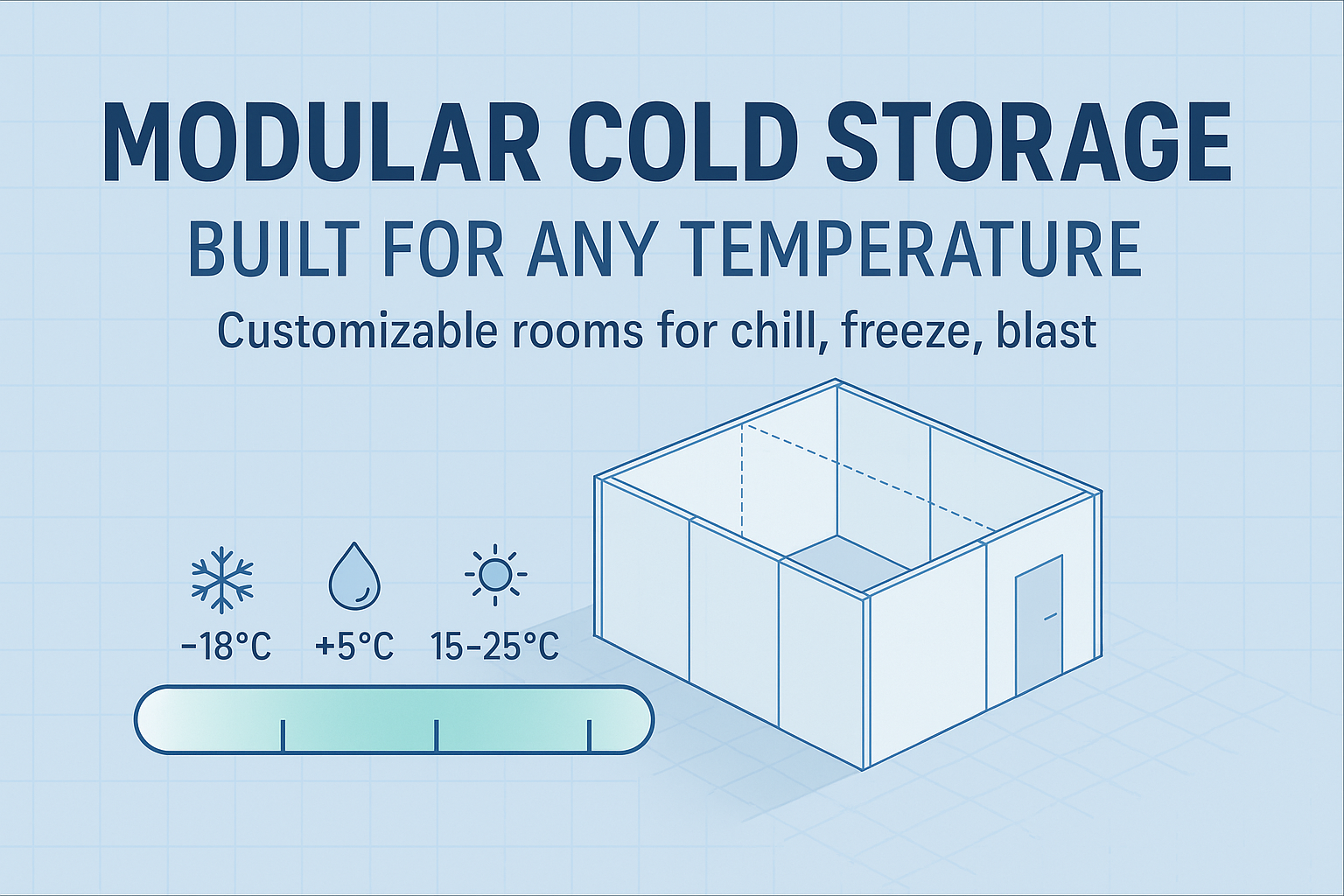

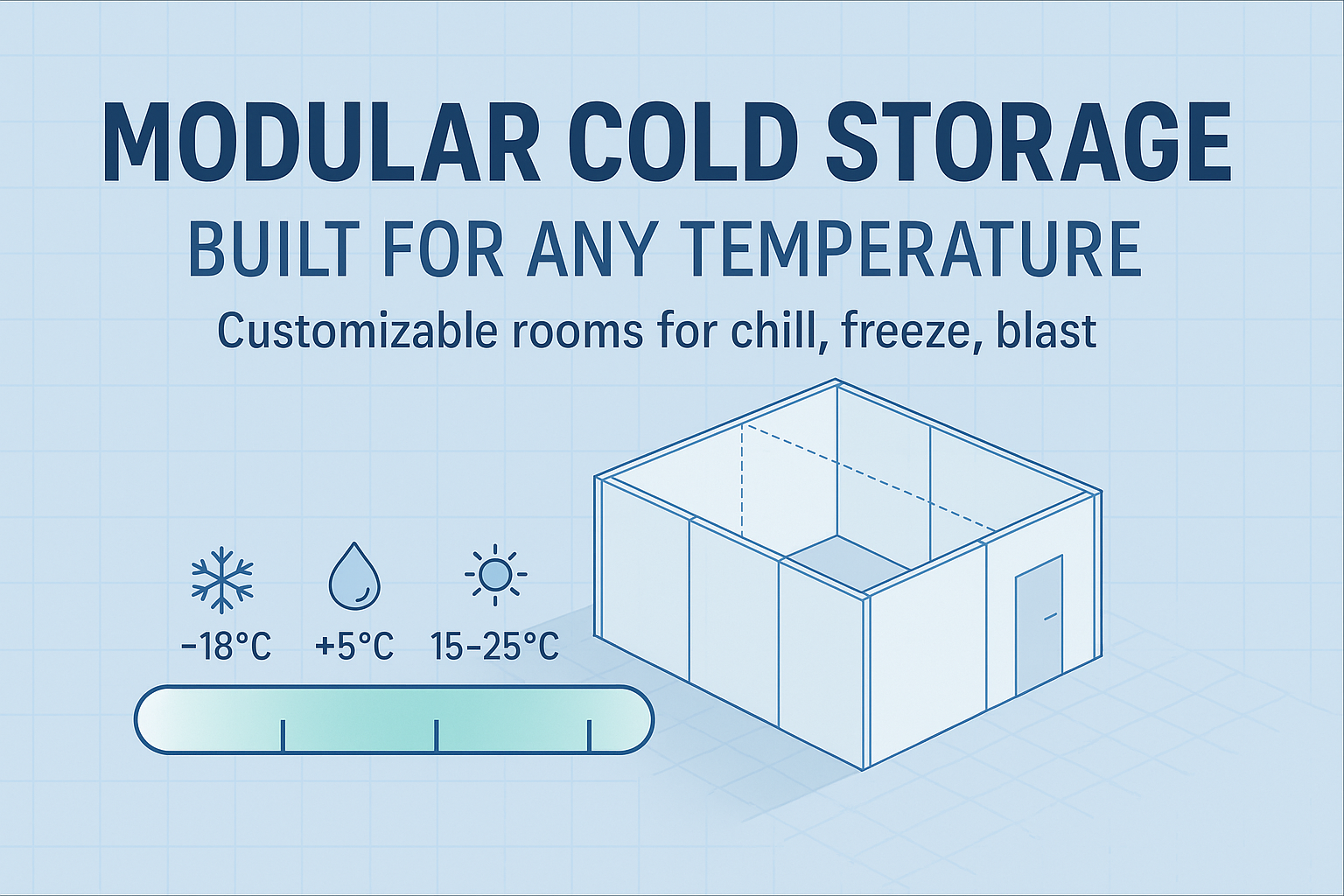

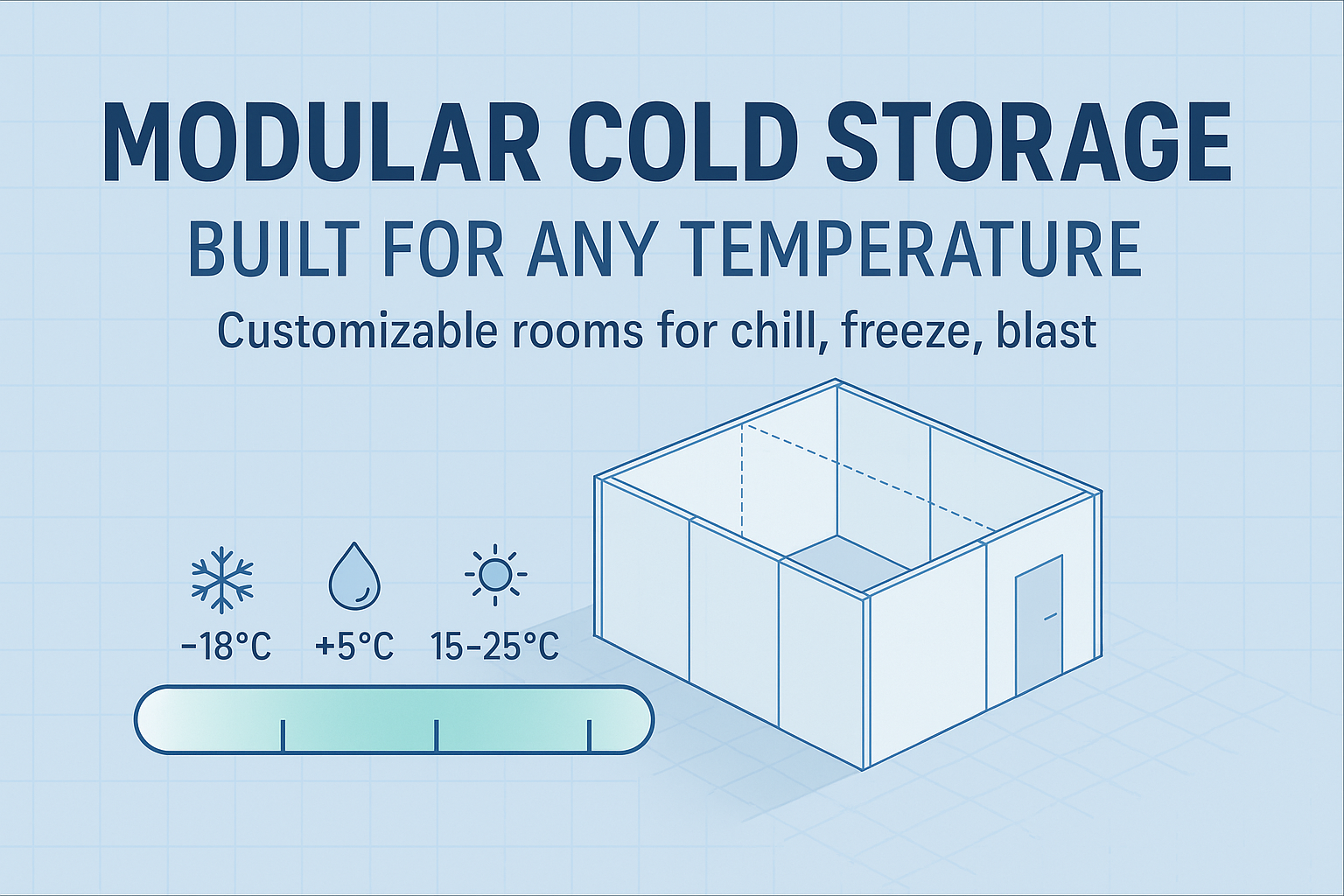

Summary: Modular cold storage is built from insulated panel “modules” that assemble into rooms you can size, zone, and equip for different temperature (and humidity) setpoints—from ambient-controlled staging areas to chill, freeze, and even blast-freeze applications. Customization spans the envelope (panel thickness/U-values), floors, doors, refrigeration plant, and controls/monitoring—plus programmatic requirements if you handle regulated goods (food, pharma). The result is a configurable facility that can match product-specific specs and compliance obligations.

Modular cold rooms use factory-made insulated panels that lock together to form spaces of almost any footprint and height; panel thickness and joint design are selected to hit required thermal performance (U-values) and hygiene targets. For example, PIR panel ranges show how thickness changes U-value, which directly affects energy and temperature stability.

Why it matters: The ability to right-size panels, doors, and plant lets you create multi-temperature sites (e.g., +2 to +5 °C chill, ≤ −18 °C frozen) and scale later by adding or reconfiguring modules. Regulatory frameworks don’t mandate one temperature for all foods; they require you to maintain product-appropriate temperatures and verify you can do so.

Chilled storage (~0 to +5 °C / ≤ 41 °F) for many time/temperature control for safety (TCS) foods at retail and food service. (Warehousing should align with the product’s specification and hazard analysis.) FDA’s Food Code anchors cold holding at 41 °F (5 °C) or below for TCS foods.

Frozen storage (≤ −18 °C / 0 °F) is widely referenced for frozen foods; Codex materials cite −18 °C maintenance and warn against attempting to “freeze during transport.”

Blast chilling/freezing requires rapid pull-down. U.S. DOE test methods set target product temperatures of +38 °F for blast chill and 0 °F for blast freeze; engineering literature reports evaporator temperatures commonly −35 to −52 °C in blast freezers (system-level, not room air).

Pharma temperature-controlled storage often uses mapped ranges such as 15–25 °C, 2–8 °C, or −25 to −10 °C, depending on product labeling; WHO guidance requires temperature mapping for any labeled-temperature storage area.

Bottom line: Your setpoint and drift/tolerance bands should follow the product spec or label and your hazard/risk analysis, then be validated and monitored.

Panel thickness/U-value: Choose panel thickness to meet your target U-value (and local energy code). Published PIR panel tables show the U-value reductions as thickness increases.

Walk-in energy standards: In the U.S., DOE standards require minimum envelope insulation for walk-in coolers/freezers (e.g., R-25 walls/ceilings/doors for coolers; R-32 for freezers; R-28 freezer floors). These are helpful benchmarks even for modular rooms.

Vapor retarder design: Correct vapor retarder placement (interior vs. exterior encapsulation) prevents condensation/ice within assemblies—called out in cold-storage roof/wall design guides.

Insulation + frost-heave protection: Freezer slabs require adequate floor R-value and sub-slab heat (glycol or electric) to keep subgrade above freezing; reputable design guides and case papers detail the rationale and methods.

Swing rooms & future reconfiguration: Many modern facilities design rooms that can swing between +35 °F and −20 °F, or add new “swing” rooms later—illustrated by recent multi-tenant builds and expansions in the sector.

High-speed, tight-sealing doors and vestibules reduce air/moisture infiltration, helping temperatures hold and lowering energy load; industry studies and technical notes emphasize cutting doorway heat/moisture gain.

Plant options: From small, dedicated condensing units to larger centralized racks—selected based on load profiles, future swing needs, and energy strategy; ASHRAE’s Refrigeration Handbook is the primary engineering reference.

Monitoring & alarms: Food facilities must use accurate, maintained instruments for measuring/recording temperature; certification standards expect recording equipment with alarms to demonstrate control.

Design to the dew point: Airflow control, dehumidification, and correct envelope details prevent condensation/ice that can compromise hygiene and safety. Extension guidance outlines practical measures to keep moist air off cold surfaces.

Food (U.S.)

cGMP & Preventive Controls (21 CFR Part 117): Requires you to identify hazards and implement preventive controls (including temperature) with accurate, maintained instruments and appropriate records.

BRCGS Storage & Distribution (GFSI-benchmarked): Expects storage areas to maintain product temperature within specification and to operate with temperature recording + alarms.

Sanitary Transportation (21 CFR 1 Subpart O): If you load/dispatch, you must verify refrigerated compartments are prepared and document procedures to ensure adequate temperature control during transport.

Pharmaceuticals / life sciences

WHO temperature mapping & GDP: Mapped storage areas (e.g., −25 to −10 °C, 2–8 °C, 15–25 °C) with ongoing monitoring, calibration, and record retention (at least shelf life + one year, or per national law).

USP <1079> series / ICH stability: Align storage ranges and excursion handling with label claims, stability data, and Mean Kinetic Temperature (MKT) principles.

Energy & building

Walk-in standards (10 CFR 431 Subpart R) guide minimum insulation and component efficiencies for coolers/freezers; ASHRAE 90.1 adds envelope and thermal bridge controls that influence panel choices and detailing.

Key takeaway: Regulations don’t prescribe “one temperature fits all.” They require you to design, validate, monitor, and document that each room meets the product’s temperature specification—using auditable instruments, alarms, and records.

Products & ranges: List each commodity/drug class with its labeled/spec range (e.g., 2–8 °C milk; ≤ −18 °C frozen foods; 15–25 °C excipients).

Room setpoints & tolerances: Target, high/low alarms, and corrective-action thresholds.

Envelope: Panel type, thickness/U-value, thermal-bridge strategy, vapor retarder location; freezer floors with R-value and frost-heave protection.

Doors & openings: High-speed or sliding doors, vestibules/air management, and interlocks to limit infiltration.

Refrigeration: Equipment type (dedicated vs. central), capacity at design ambient, pull-down needs (blast), redundancy strategy (N+1 where risk warrants).

Controls & monitoring: Calibrated sensors, data logging frequency, alarm routing, temperature mapping plan and re-qualification cadence.

Records & audit: Retention period (at least shelf life + 1 year for pharma; align food records with your HACCP/PC plan), change control, and CAPA workflow.

Future-proofing: Provisions for convertible/swing rooms and additional penetrations or circuits to add chillers/evaporators later.

Very. In practice, modular buildings let you tailor:

Number/size of rooms (including convertible “swing” rooms).

Envelope performance (panel thickness/U-value to meet DOE and local energy codes).

Floor assemblies (insulation and under-slab heat for freezers).

Door systems (high-speed/airtight to cut infiltration).

Plant & controls (from light-duty chill to heavy-duty blast; mapped monitoring with alarms).

What customization cannot replace is your specification discipline: define product ranges, validate performance (e.g., mapping), and keep auditable records. That’s what regulators and certification bodies look for.

FDA 21 CFR Part 117 (cGMP/Preventive Controls).

FDA 21 CFR 1 Subpart O (Sanitary Transportation).

FDA Food Code 2022 (retail TCS cold holding at 5 °C / 41 °F).

BRCGS Storage & Distribution (temperature maintenance, recording, alarms).

WHO temperature mapping & GDP recordkeeping/calibration.

DOE 10 CFR 431 Subpart R (walk-in cooler/freezer envelope minimums).

ASHRAE Refrigeration Handbook (systems and applications).

Envelope & floor design references (vapor control; frost-heave prevention).

Modular cold storage offers extensive customization—but compliance hinges on proving control: the right design (panels, floors, doors), validated performance (mapping), and reliable monitoring/alarms with appropriate records. If you share your product list and target ranges, I can turn the checklist above into a room-by-room spec outline that aligns with your jurisdiction and certification goals.

September 13, 2025

September 7, 2025

August 29, 2025

August 24, 2025