Cold Storage for Apples and How Does It Work

Admin

September 19, 2022

September 19, 2022

Apple, a favourite among consumers is also a commercially important fruit for farmers and distributors. To ensure that producers get the best ROI post-harvest and consumers equally enjoy the flavoursome fruit at any time of the year, cold storage for apples has become a crucial component of post-harvest management.

Usually, after harvesting, apples undergo a series of steps before reaching the end customer including pre-cooling, grading, storing, packaging, transportation, and finally marketing. In this article, we will primarily focus on cold storage to help businesses make the right decision!

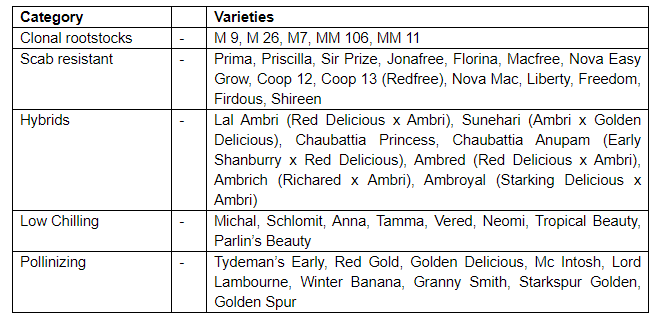

Some of the important varieties cultivated in India include the following.

Let us understand the step-by-step storage process in brief.

The requirements for pre-cooling or rapid cooling depend on the produce and method of cooling such as room cool, hydro cool, forced air cooling, evaporative forced air cooling and ice packaging. After harvesting, the apples must be immediately placed in a cool and ventilated place to remove field heat before packing. It is important to remove dirt and moisture from the fruit surface before grading and packing in cartons.

Apples are usually not injured by rapid cooling. A delay of 1 day in the orchard at 21°C after harvest may shorten the storage life by 7 to 10 days at 0°C. Whereas, a delay of 3 days in the orchard or in a warm packing shed may shorten the storage by 30 days, even if they are subsequently stored in a controlled atmosphere at -1°C.

Grading is done on the basis of the size and appearance of the fruit. divided into six grades based on the size. Depending on the fruit’s colour, shape, quality and appearance, apples can be graded in different quality grades such as s AAA, AA and A; A, B, C; or extra fancy, fancy class I and fancy class II.

In some cases, orchard-run apples are treated with diphenylamine to prevent storage scald. If packed boxes or cartons are used, then they should have this treatment if the variety is susceptible to scald.

Also, some varieties, such as Golden Delicious, are prone to water loss and that is why fruit boxes or bulk bins can be covered with polyethylene film. It is advised that the covers should not be sealed because the apples may develop an off flavour.

Controlled atmosphere (CA) storage help maintain desired oxygen and carbon dioxide levels which help slow down the ripening process, prevent some storage disorders (scald in apples) and also minimise the growth of decay organisms. This prolongs the shelf-life of the perishables when compared to regular refrigerated stores and that is why CA storage facilities are recommended for the long-term storage of apples, kiwis, pears, cabbages, etc. for up to 10 months.

During storage, the quality of apples depends on the fruit maturity at the time of harvesting, delay before cold storage, storage temperature, and the presence of other items in the room. For instance, apples can absorb the odour from celery, cabbage, carrots, potatoes and onions and are therefore not stored in the same room. Moreover, meat, egg, and dairy products can absorb odour from apples and should not be stored together.

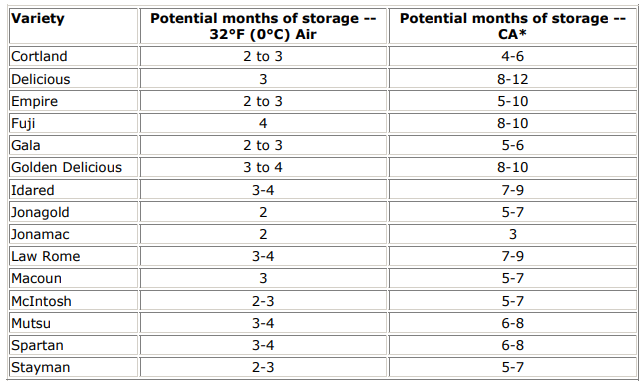

Storage duration also depends on the variety. McIntosh ripens quickly at 32°F (0°C) and has a short storage life whereas Rome ripens slowly at 32°F (0°C) and can be stored for longer. Susceptibility to diseases and disorders can also shorten the storage duration. Climatic conditions, handling, and even the orchard culture can have an impact on storage life.

Here are some key features of a typical layout of CA cold stores.

Cold storage for apples is an essential part of post-harvest management. With the right storage conditions and CA cold storage facilities, farmers and producers can not only reap maximum profits but also ensure customer satisfaction with quality produce.

Rinac, an industry-leading provider of cold storage solutions has developed world-class cold storage and controlled atmosphere facilities to help small and big businesses reduce wastage and improve profit margins! To know more about our cold storage solutions and how we can help you, get in touch with us today!

September 30, 2024

September 23, 2024