All You Need to Know About Banana Ripening Chambers

May 19, 2022

May 19, 2022

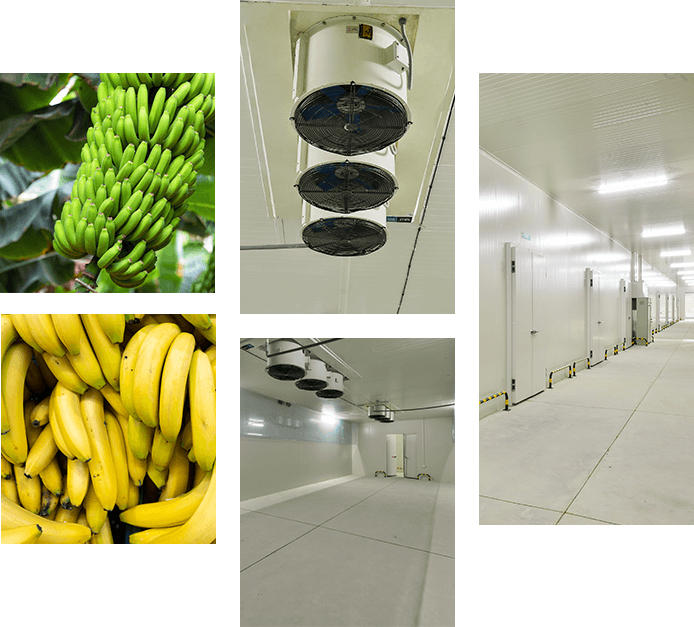

In the food industry, delivering fresh, high-quality produce to customers is a priority for businesses. This means finding a balance—the farmers get the right value for their produce, the traders get the right market price with reduced wastage, and finally, the consumers get the produce with intact natural texture and flavour. Since perishable items such as banana, tomato, mango, or papaya are more prone to deterioration with changes in temperature and moisture content, it is important to adopt effective ripening solutions that increase the shelf-life as well as maintain the nutritional characteristics and flavour.

In this article, we will discuss what banana ripening chambers are, how they work, and how they can help your business maximize profitability.

Bananas are highly perishable items and especially in high temperatures with an accelerated ripening process, the shelf-life is reduced to just a day or two. Therefore, bananas are harvested raw at an appropriate stage and ripened and stored in specially designed chambers to increase the shelf-life.

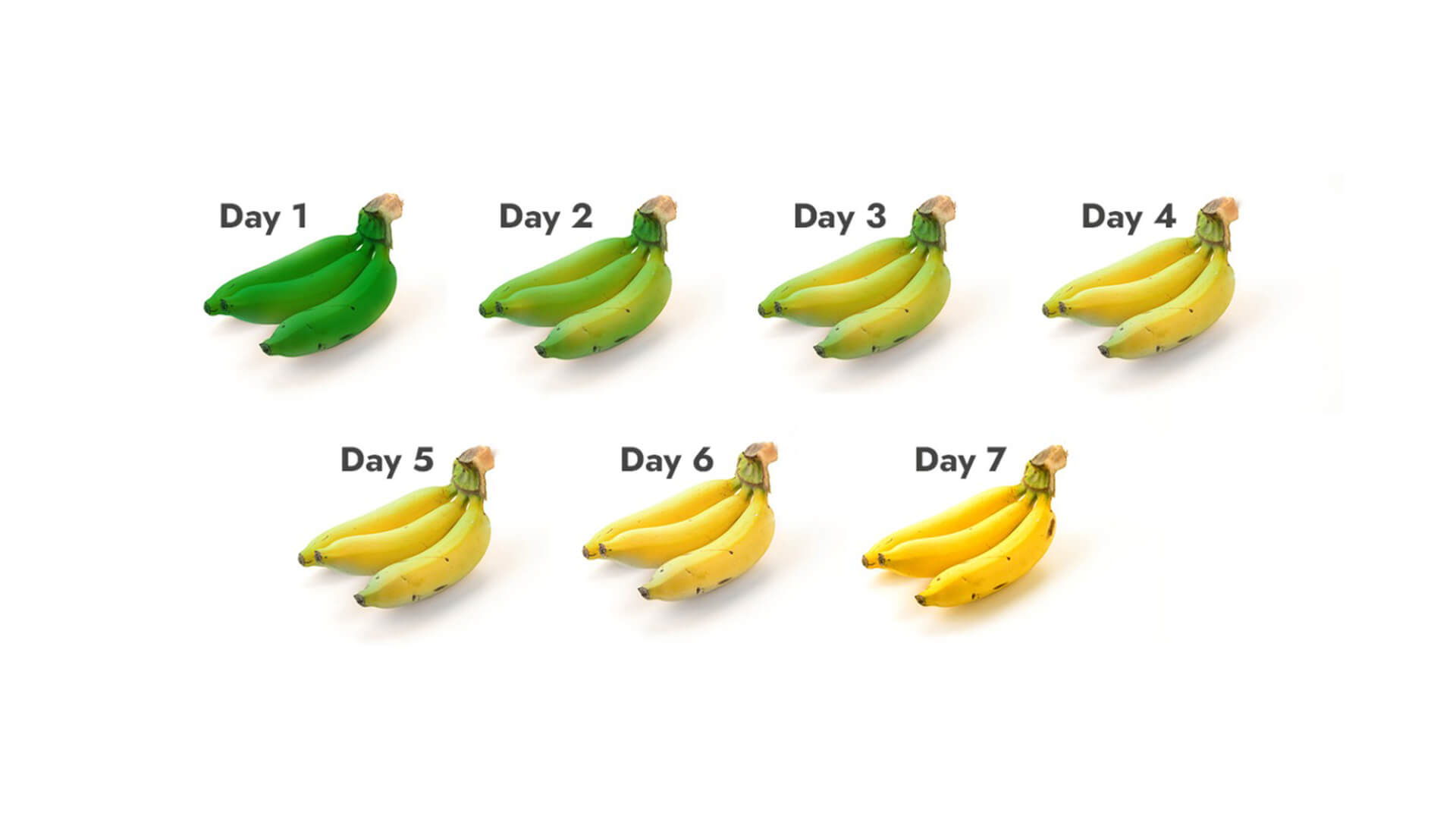

Banana ripening chambers stimulate the natural process of ripening by controlling the temperature and release of ethylene gas, reducing the ripening process to four to six days for the best quality. These ripening chambers are faster than the traditional ripening process and prove beneficial both to the farmers and the traders.

These banana ripening chambers are safer than the use of calcium carbide to expedite the ripening process. Calcium carbide, which is generally used in welding applications, has been proven to be toxic and carcinogenic. It has been, therefore, banned by policymakers and its use is prohibited under section 44 A of the Prevention of Food Adulteration Act.

Ethylene gas on the other hand is a scientifically proven and globally accepted method of ripening. Usually, a fruit is exposed to a very small amount of ethylene to stimulate its ripening process until the fruit starts producing ethylene naturally to ripen in a controlled environment, producing the best result. Moreover, since ethylene is a natural hormone in plants, it does not pose any health hazard and is also a detraining agent which turns the peel from green to perfect yellow, maintaining the sweetness and aroma of the fruit.

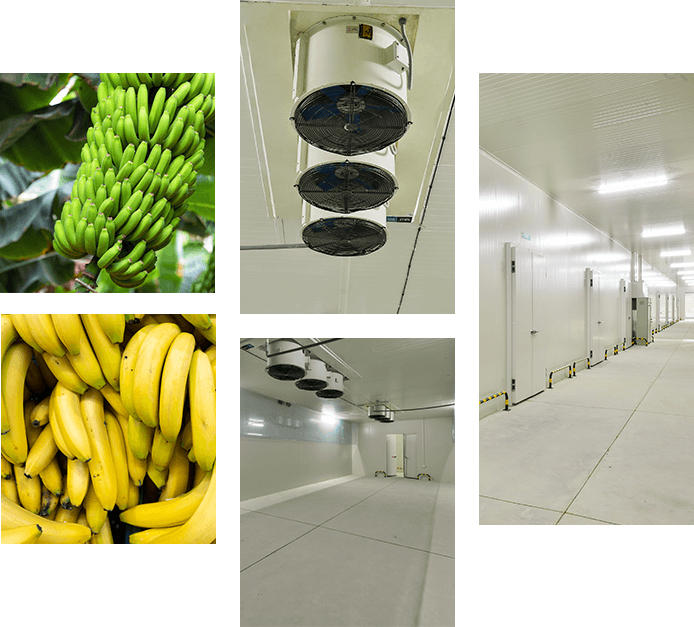

A standard banana ripening chamber consists of the following components.

For bananas, a temperature range of 13 to 14°C and 90 to 95% RH (relative humidity) is considered ideal for storage and transport and a temperature of 15 to 20°C with 90 to 95% RH is ideal for ripening.

Usually, the banana ripening chamber is operated between four and six days for one cycle. The cycle may consist of the following steps.

To meet the varying needs of traders and farmers, these ripening chambers are available in different sizes and refrigeration capacities.

Customers are becoming more conscious about sustainability as well as the quality of fresh produce. That is why traders and farmers need to adopt ripening chambers that are not only environmentally-friendly and maintain the quality of fruits and vegetables.

Rinac, a pioneer in cold chain solutions, offers standard banana ripening chambers which provide the most cost-effective and environment-friendly solution for ripening fruits. To know, how Rinac can help you get more value for your produce, visit here