Cold Storage for Mangoes and How Does It Work

Admin

September 27, 2022

September 27, 2022

Mango or Mangifera indica L. is rich with flavour and aroma and that is why it is rightly the national fruit of India as well as the king of fruits! In fact, in India, mango is cultivated in the largest area of 2.218 million ha with a production of around 18.832 million MT and a productivity of 8.49 MT/ha. However, post-harvest handling of mango due to its climacteric nature remains a challenge. That is why post-harvest handling plays a critical role in reducing losses for both farmers and traders which account for 25 to 30% of the total loss. This is primarily due to a lack of low-temperature storehouses and robust cold chain infrastructure for storage and transportation.

In this article, we will briefly discuss cold storage facilities for mangoes and how you can utilise them to maximise your margins.

More than 30 varieties of mango are grown commercially but a few important ones include Alphonso, Banganpalli, Chausa, Dashehri, Langra, Totapuri and Kesar. Storage conditions and shelf-life may vary depending on the variety of the fruit.

Here are some of the important steps involved in the handling and processing of mango fruit.

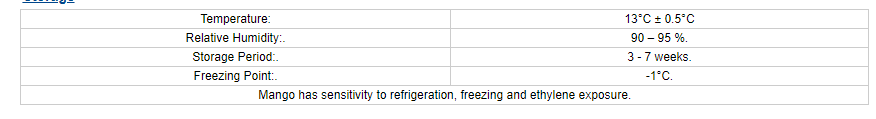

General guidelines from APEDA

However, there are some associated issues with inefficient cold storage including power back-ups and generators to maintain proper functioning with appropriate conditions. Additionally, after the removal of fruits from the storage, there is perspiration on the fruit surface which requires at least two hours of waiting period until the next operation.

Many experts and segments of the trading community are in favour of controlled atmosphere (CA) cold storage with ULO (Ultra Low Oxygen). These methods do not require modified atmosphere packaging (MAP) and may also increase the storage duration up to six to seven weeks. With that being said, there are some concerns with CA storage for mangoes such as fruit softening, poor colour development and higher titratable acidity (TA), and reduced aroma and flavour.

Better handling and storage of mango means better quality which translates to happy customers and improved profits! Appropriate cold storage conditions are, therefore, necessary for prolonged shelf-life and reduced post-harvest decay. That is why when choosing cold storage for your harvest, make sure to look for experience, expertise, and strong technical support.

Rinac is a leader in cold chain solutions offering services for customised and turnkey projects for controlled atmosphere (CA) chambers, modified atmosphere (MA) chambers, ripening rooms, pre-cooler rooms, refrigerated transportation and much more to enhance the value of your post-harvest produce!

To know more, get in touch with us today!