Understanding the durability and insulation properties of prefabricated sandwich panels

For cold chain, food & beverage plants, pharma cleanrooms, ripening rooms, and modular buildings—what matters for long life and dependable thermal performance in Indian conditions.

Where sandwich panels fit in India

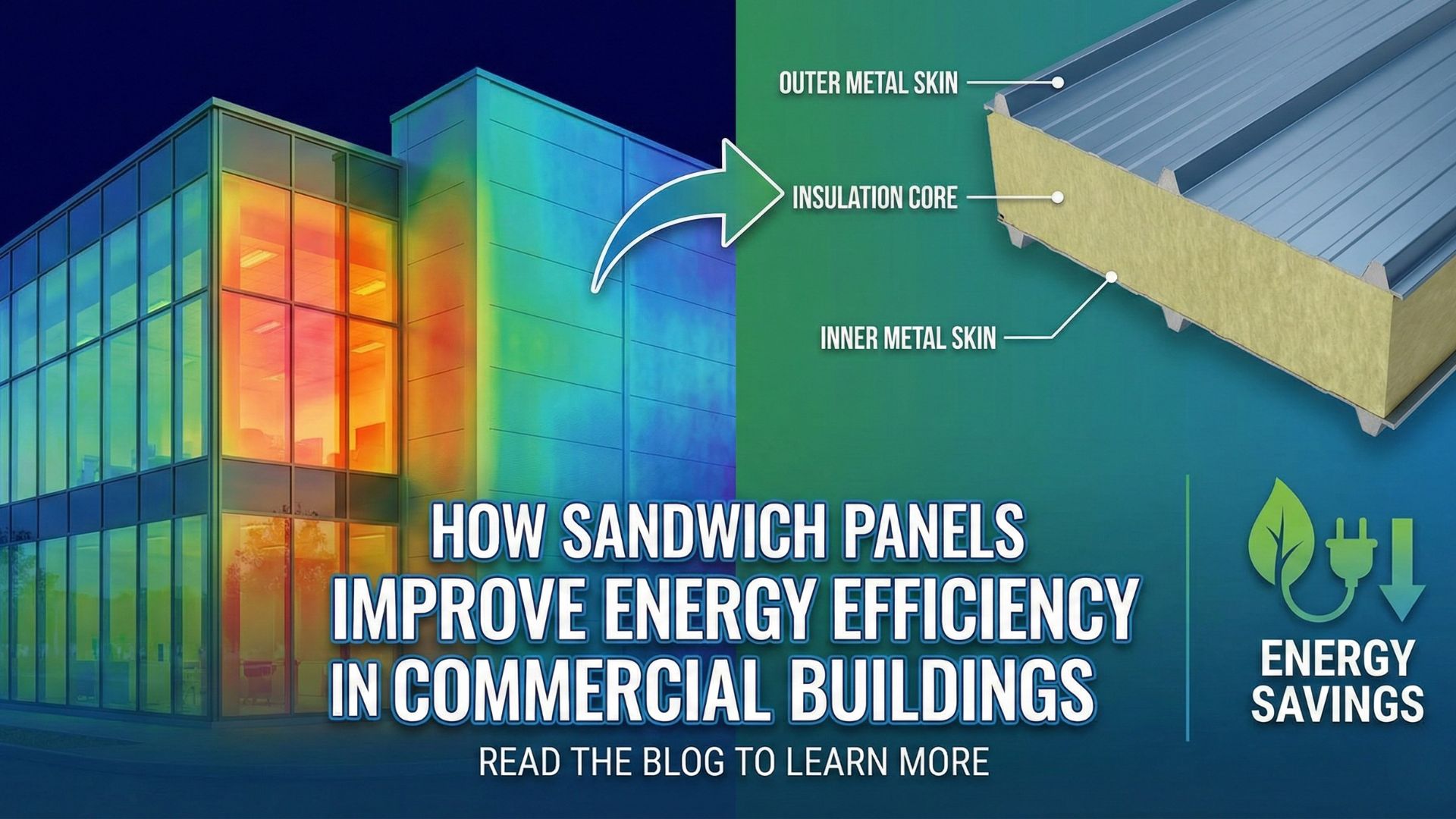

Prefabricated sandwich panels are factory-made wall/roof elements with metal facings bonded to an insulation core. They’re widely used in India across cold chain facilities, cleanrooms, and modular enclosures—the same segments Rinac serves.

Indian Standard IS 16203:2016 defines requirements for prefabricated polyurethane sandwich panels (PUF/PUR/PIR), including core characteristics, typical thicknesses (30–200 mm), and interlocking joints (tongue-and-groove with or without mechanical locks) that help achieve airtightness—essential for cold rooms and controlled environments.

Insulation performance: what actually drives energy efficiency

Thermal conductivity (λ)

The core’s thermal conductivity is the single biggest driver of U-value. Indian Standard IS 12436 (for preformed rigid PUR/PIR foams) specifies typical λ values of 0.023 W/m·K at 10 °C mean temperature (and 0.030 W/m·K at 50 °C), which explains why PIR/PUF cores are preferred in cold applications.

Mineral wool cores have a higher λ (i.e., lower thermal resistance per mm) but offer non-combustibility—useful wherever fire performance drives material choice (e.g., certain clean/process areas). Rock/mineral wool cores are commonly supplied and marketed in India/Asia for sandwich panels with Euroclass A1 non-combustibility.

Practical takeaway: For cold rooms and ripening chambers that prioritise energy savings, PIR/PUF cores help minimise wall/roof thickness for a target U-value; where regulations or risk assessment emphasise fire non-combustibility, mineral wool is often selected (accepting thicker panels for the same U-value).

Joints, vapour and air control

IS 16203 calls for interlocking joints; pairing these with suitable gaskets/sealants reduces air leakage and vapour ingress, protecting R-value and preventing interstitial condensation/ice. Test methods referenced in IS 16203 (e.g., IS 11239 for water-vapour transmission and compressive strength; IS 3346/9489 for thermal measurements) provide a consistent framework to verify performance.

Durability: how panels deliver a long service life

Durability is a system property—it depends on materials, coatings, bonding quality, and detailing:

- Metal facings & coil coatings

In India, facings are typically hot-dip aluminium-zinc alloy coated steel to IS 15961 and pre-painted to IS 15965, or hot-dip galvanised to IS 277. The standards cover base metal thickness ranges, coating systems (e.g., polyester/fluoropolymer families), mechanical properties, and corrosion testing (e.g., salt-spray). Choosing the right substrate and paint system for coastal/industrial atmospheres is central to longevity. -

Core–facing bond & mechanical performance

IS 16203 lists required tests for the panel build-up (materials and finished panels) and references IS 11239 (rigid cellular insulation test methods) to check properties like compressive strength and stability—critical to handling loads, suction, and impacts during service. - Joint integrity and accessories

The standardised tongue-and-groove geometry (with or without mechanical locking devices) supports consistent joint compression and sealing, which helps maintain hygiene and thermal consistency in cold and clean areas. -

Wind, weather and structure

For roofing and external walls, structural checks for local basic wind speed and suction per IS 875 (Part 3):2015 help ensure fastener patterns, spans, and support framing are adequate—key to preventing fatigue, leakage, and premature wear in monsoon and cyclone-prone zones. - Fire and life safety (system level)

India’s National Building Code (NBC 2016, Part 4) sets out fire/life-safety provisions, fire zoning and occupancy classification; panel core choice (PIR/PUF vs mineral wool), internal linings, and fire-stopping at penetrations should be aligned with the project’s approved fire strategy under NBC and the local Authority Having Jurisdiction.

What this means for typical Rinac applications

-

Cold rooms & cold warehouses

Prioritise low λ cores (PIR/PUF) to reduce running energy. Use interlocking joints with appropriate gaskets/sealants; verify panel thickness vs design U-value using λ per IS 12436. For roofs/external walls, size spans/fasteners to IS 875 Part 3. -

Ripening rooms & processing areas

Where temperature and humidity are high, select coil coatings to IS 15965 suitable for the environment; where the fire strategy demands non-combustible elements, consider mineral wool cores for the relevant zones. - Pharma/cleanrooms & hygienic spaces

Focus on airtightness, cleanable facings to Indian coil-coating standards, sealed junctions, and compliant fire strategies per NBC Part 4

How to specify—India-ready, compliance-friendly checklist

-

Reference the right Indian standards in tender/specs

- Panels: IS 16203:2016 (Prefabricated Polyurethane Sandwich Panels—Specification).

- Foam core: IS 12436 (Rigid PUR/PIR foam for thermal insulation).

- Metal facings: IS 15961 (aluminium-zinc alloy metallic coated steel, plain), IS 15965 (pre-painted), and/or IS 277 (hot-dip galvanised).

- Design loads (wind): IS 875 (Part 3):2015.

- Fire & life safety: NBC 2016 Part 4 (project-specific route).

- State thermal targets clearly

Ask vendors to declare design U-values for the proposed thickness and temperature regime, with core λ at 10 °C per IS 12436 or test references listed in IS 16203 (IS 3346/9489). - Detail joints and vapour control

Require interlocking (T&G) joints per IS 16203, continuous gaskets/sealants at all laps and corners, and vapour-tight detailing around doors and floor-wall junctions to prevent condensation/ice. - Match facings/coatings to environment

For coastal/industrial atmospheres, specify aluminium-zinc alloy coated steel to IS 15961 and pre-painted systems to IS 15965 with agreed corrosion testing; for standard interior applications, IS 277 compliant galvanised options may suffice—confirm with the risk/environmental assessment. - Ask for test evidence

Use the test methods cited in IS 16203 (e.g., dimensional stability, water-vapour transmission, compressive strength) and IS 12436 to build a submittal checklist. - Wind design & fastening

Ensure panel spans, clip/fastener type, spacing, and pull-out values are checked against IS 875 Part 3 for the project location’s basic wind speed map. - Fire strategy alignment

Select core type (PIR/PUF vs mineral wool), cavity barriers, and penetrations to meet the project’s approved NBC Part 4 route; avoid generic claims and rely on project-specific approvals.

Typical data you’ll see in compliant submittals

- PIR/PUF core λ: around 0.023 W/m·K at 10 °C mean temperature per IS 12436—use this to calculate U-values for given thicknesses.

- Panel build & joints: IS 16203 specifies interlocking joints (T&G) and lists tests and tolerances for the panel system.

- Facings & coatings: Referenced to IS 15961/15965 (aluminium-zinc alloy metallic coated & pre-painted steel) or IS 277 (galvanised) with agreed corrosion testing protocols.

- Fire framework: Compliance demonstrated against NBC 2016 Part 4 for the relevant occupancy and fire zoning.

Final word

A durable, energy-efficient sandwich panel enclosure comes from choosing the right core, specifying Indian-standard facings and coatings, detailing airtight joints, and checking wind and fire compliance against IS and NBC requirements.