Why India Still Loses So Much Food (and Money)

Nearly 40 % of all food produced in India is wasted, and roughly a third of those losses come from inadequate cold storage and logistics. ICAR studies place post-harvest losses for fruits at 5.8 – 18 % and vegetables at 6.8 – 12.9 % — all before produce even reaches market.

At the same time, cold storage is power-hungry: India’s pack-house electricity demand alone could jump from 2.4 TWh in 2018 to 5.2 TWh by 2038 if efficiency doesn’t improve . With grid tariffs hovering around ₹8–10 / kWh in many states, reducing refrigeration load directly protects margins and frees capital for growth.

What Makes a “Modern” Cold Storage Solution?

1. Advanced Insulation & Modular Construction

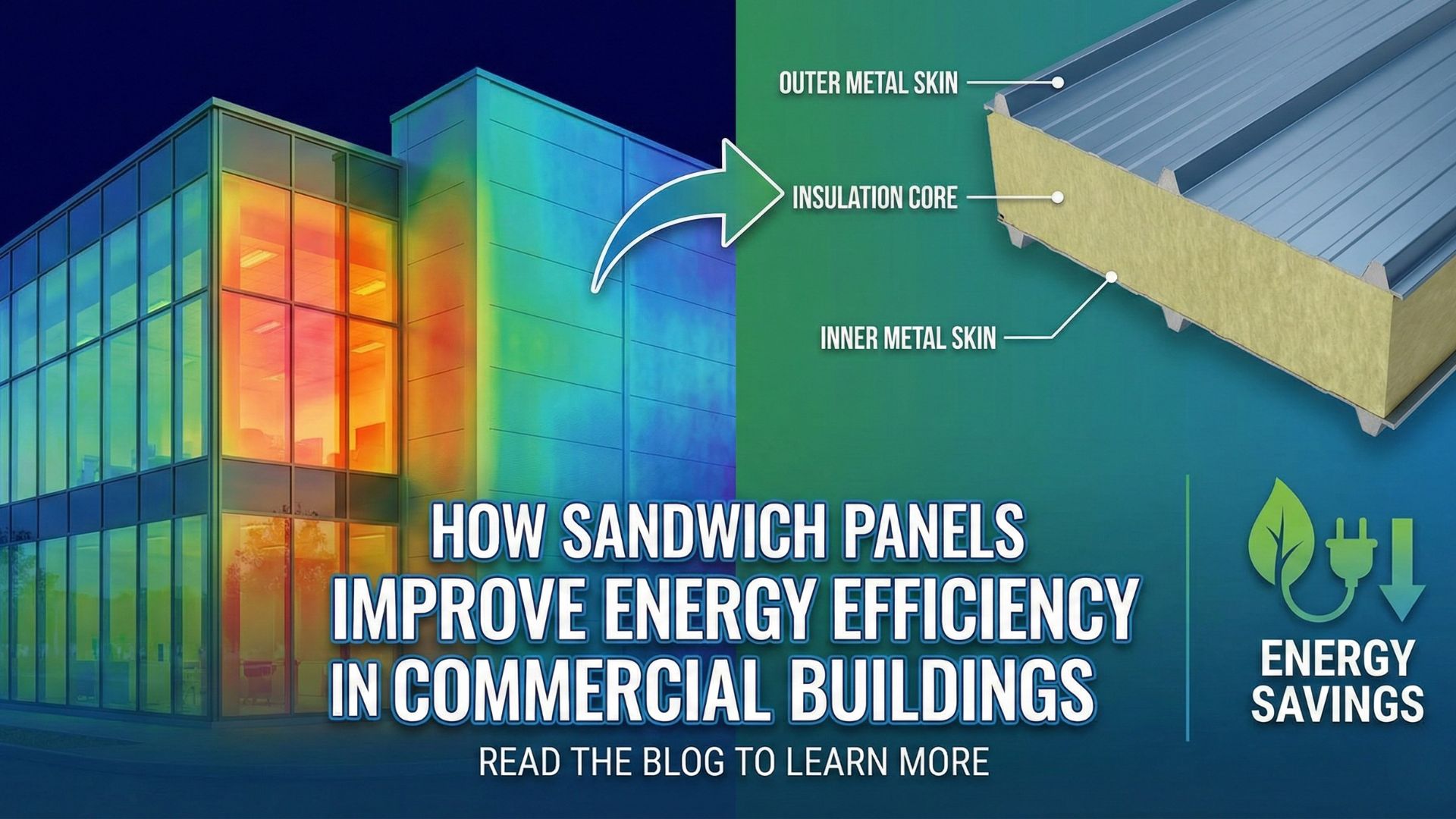

- RPUF/GRP panels slash thermal leakage versus brick-and-mortar rooms. See Rinac’s Step-In Chillers & Freezers and Multi-Commodity Warehouses for examples.

- Modular designs install 30–40 % faster, keep construction waste low, and let operators scale capacity in phases.

2. High-Efficiency Refrigeration

- Variable-frequency drives (VFDs), EC fans, and high-COP compressors can cut energy use 25–35 % versus fixed-speed systems

- Opt for low-GWP refrigerants; they future-proof compliance and lower indirect climate costs

3. Renewable & Hybrid Power

- Solar-assisted cold rooms now qualify for multiple state subsidies and routinely deliver 3–5-year paybacks in high-irradiance regions

- Battery-backed or eutectic “thermal battery” systems featured in Rinac keep temperatures safe during outages without diesel gensets.

4. Smart Monitoring & IoT

- Cloud dashboards and SMS alerts flag door abuse, set-point drift, or power failure instantly, trimming spoilage by up to 15 %.

- Data logging is mandatory for many pharma and export audits; having it embedded avoids retrofits later.

5. Rapid-Response Doors & Air Curtains

Fast PVC roll-up doors and properly sized air curtains can lower infiltration load by 10 %+ in high-traffic stores.

Proven Results from the Field

| Installation | Problem Solved | Outcome |

|---|---|---|

| Bastar, Chhattisgarh (state-run 2,500 t store) | 7–20% annual produce loss due to heat & pests | New cold facility projected to save ₹8.5 cr / year and extend shelf-life for tamarind, millet, etc. |

| Retrofit of 20-year-old potato stores, UP | 30% higher kWh/t vs. modern standard | Envelope & VFD upgrade cut energy intensity by 38%, payback 2.9 years |

| Rinac “LiteCold” modular rooms (case study) | SMEs lacked space & cap-ex | Plug-and-play rooms deployed in 14 days; energy bills 28% lower than masonry chillers (internal metering). |

Best Practices to Maximise ROI

- Start at the Farm Gate – Pre-cool within 2 h of harvest to remove field heat (pack-house grants available under MIDH).

- Match Room to Commodity – Separate high-respiration produce (e.g., mango) from low; avoid over-cooling mixed loads.

- Implement Preventive Maintenance – A dirty condenser can hike power draw 15 %. Weekly coil cleaning pays for itself.

- Train Staff – Door discipline alone can save 3–5 kWh / day in a 100 m³ store.

- Leverage Government Incentives – PM Kisan Sampada Yojana subsidises up to 35 % of plant cost for integrated cold chains

The Financial Case

- Revenue uplift: Fresher produce commands 10–20 % higher farm-gate prices

- Energy savings: Modern systems trim ₹6–8 lakh per MW-h saved annually in a 1,000 t multi-commodity store (based on ₹9 / kWh tariff and 0.8 PF).

- Market tailwinds: India’s cold storage sector is expanding at 11.7 % CAGR through 2030 , fuelled by e-commerce groceries, dairy, and vaccines.

Getting Started with Rinac

Rinac has delivered 3,000+ cold projects across India over three decades. Whether you need a compact walk-in chiller, a solar-ready warehouse, or a portable reefer, Rinac’s engineering team can size, install, and maintain a turnkey solution that slashes spoilage and power bills from day one.

Ready to future-proof your cold chain?

Talk to Rinac’s specialists about a custom cold storage solution that keeps every kilogram fresh, cuts your energy spend, and boosts profitability.