How Sandwich Panels Improve Energy Efficiency in Commercial Buildings

Audience: Commercial and industrial building owners, cold chain operators, food processors, pharma/healthcare facility teams, and EPC/PMC decision-makers across India who want measurable energy savings without compromising uptime, hygiene, or safety.

TL;DR

- Sandwich panels reduce heat gain/loss by combining a high-performance insulated core with durable metal skins, lowering HVAC and refrigeration loads.

- Airtight joints matter as much as insulation thickness because uncontrolled air leakage increases cooling/heating demand and humidity loads.

- Continuous insulation helps hit ECBC-style envelope performance targets, especially for 24/7 facilities like cold stores, cleanrooms, and process plants.

- Right spec = right core + right thickness + right detailing (joints, penetrations, doors, roof-wall junctions, and vapour management).

Executive summary

In India, energy costs and harsh climate conditions (hot, humid, coastal, dusty, and high-UV regions) make building envelope performance a major lever for lowering operating expenses.

Insulated sandwich panels improve energy efficiency by reducing conductive heat transfer through walls and roofs, limiting infiltration when properly sealed, and supporting fast, consistent installation quality.

This is especially valuable in temperature-controlled and hygiene-critical buildings such as cold storages, food & beverage plants, and pharmaceutical clean facilities.

Why commercial buildings waste energy

Most energy “leaks” in commercial buildings come from a few predictable places: heat transfer through walls and roofs, air leakage (infiltration), poorly detailed junctions that create thermal bridges, and moisture ingress that increases latent cooling load.

In facilities that run 24/7 (cold storage, process plants, clean manufacturing), these losses compound every hour of the year.

Two simple ideas explain most of it

- Conduction (heat passing through materials): Your wall/roof assembly has a thermal transmittance called U-value. Lower U-value = less heat transfer.

- Infiltration (uncontrolled air exchange): Gaps at joints, penetrations, and doors let hot/humid air in (or conditioned air out), forcing equipment to work harder.

For a quick mental model of conduction:

Heat gain/loss (Q) = U × Area × Temperature difference (ΔT)Reduce U (better insulation) and reduce leakage (better airtightness) and you usually reduce both energy consumption and peak equipment sizing.

How sandwich panels deliver energy savings

1) High thermal resistance with “continuous insulation”

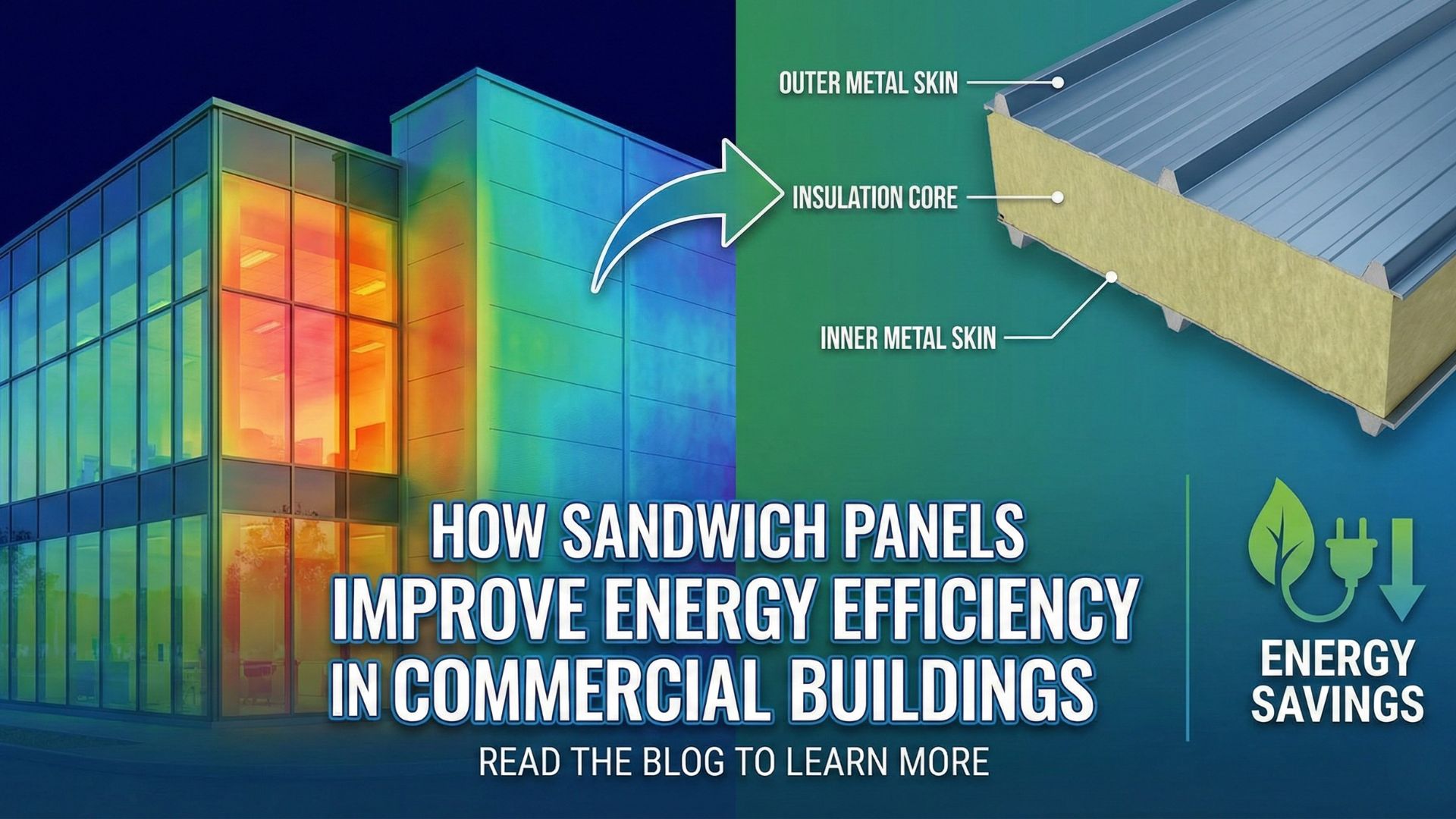

Sandwich panels combine a high-performance insulation core (commonly PIR/PUF or mineral wool/rockwool) with metal facings.

Because the insulation is continuous across large spans, the envelope can dramatically reduce heat flow compared to many site-built assemblies that have frequent thermal breaks, gaps, or inconsistent workmanship.

2) Airtight jointing reduces sensible and latent load

The insulation value on paper only becomes real savings when joints, corners, penetrations, and interfaces are sealed correctly.

Modern panel systems typically use interlocking joint profiles (for example, tongue-and-groove) that support faster installation and better air sealing when detailed and executed well.

3) Lower thermal bridging at junctions (when detailed right)

Thermal bridges are localized areas where heat bypasses insulation (for example, metal members or poorly detailed connections).

Even high-R insulation can underperform if the design ignores roof-wall junctions, door frames, floor interfaces, or fastener patterns.

Good panel detailing reduces these losses and helps maintain stable internal temperatures.

4) Moisture and condensation control

In warm-humid and coastal Indian conditions, moisture control is essential.

A well-sealed envelope reduces humid air ingress, helps prevent condensation inside assemblies, and protects insulation performance over time.

This is especially important in cold rooms, cleanrooms, and refrigerated docks where dew point conditions can be aggressive.

5) Performance that stays consistent (speed + repeatability)

Prefabricated panel construction reduces on-site variability and can shorten project timelines.

Faster closure of the building envelope means systems can be commissioned earlier and performance issues (like air leaks) are easier to detect and rectify before handover.

ECBC context in India: why envelope performance is a big deal

India’s Energy Conservation Building Code (ECBC) puts strong emphasis on building envelope performance (walls, roofs, fenestration, shading).

For projects that fall under ECBC applicability, improved envelope U-values and good insulation typically translate into both operating savings and better project economics.

For 24-hour buildings, envelope measures (especially roof insulation) can have an even bigger impact.

Practical takeaway: If your building runs long operating hours (cold storage, pharma manufacturing, hospitals, process plants),

investing in a high-performance envelope is often one of the most reliable ways to reduce both monthly bills and peak load.

How to choose the right sandwich panel specification (India-first guidance)

A) Choose the core material based on risk profile

- PIR (polyisocyanurate): Often selected for higher thermal efficiency and improved fire performance needs.

- PUF/RPUF (polyurethane foam): Strong thermal insulation and widely used across cold chain and industrial enclosures.

- Rockwool/mineral wool: Common choice where non-combustibility and acoustic performance are primary drivers.

B) Select thickness by temperature difference and operating hours

Thickness is not a one-size-fits-all number. It should be driven by:

internal setpoint (ambient, chilled, frozen, clean manufacturing),

local climate zone, expected ΔT, operating hours, and target energy cost.

For cold stores and 24/7 facilities, higher thickness typically pays back faster.

C) Don’t lose performance at the joints

- Specify joint systems designed for airtight sealing (and verify with on-site workmanship checks).

- Use compatible sealants/gaskets and detail vapour control where required (especially in refrigerated rooms).

- Plan penetrations (MEP, cable trays, sprinklers) to avoid “field fixes” that create leaks later.

D) Engineer doors, docks, and transitions

In cold chain buildings, doors and loading docks can dominate heat gain and infiltration.

Pair high-performance panels with correctly sized doors, air curtains/vestibules where needed, and disciplined operational controls.

E) Align with safety and compliance expectations

For facilities with strict fire, insurance, and safety requirements, panel selection may include fire-rated systems and globally recognized testing/approvals.

Always map material selection to the project’s risk, occupancy, and compliance requirements at concept stage.

Where sandwich panels make the biggest energy-efficiency impact

- Cold storages & distribution hubs: Lower heat gain reduces compressor runtime and helps stabilize product temperature.

- Food processing plants: Better temperature control supports process consistency and reduces HVAC energy in hygienic zones.

- Pharma cleanrooms & controlled environments: Tight envelopes support pressure regimes and reduce dehumidification burden.

- Warehouses and industrial buildings: Improved comfort in occupied areas and lower cooling loads in hot climates.

- Commercial kitchens & hospitality back-of-house: Panels help contain heat and humidity around prep/storage zones.

Implementation checklist (EPC/Projects)

- Define performance targets: internal temperatures, operating hours, target U-value/R-value, airtightness expectations, and energy KPIs.

- Choose panel system: core type (PIR/PUF/rockwool), thickness, facings (PPGI/SS/Al), and joint profile suited to the application.

- Detail thermal bridges: roof-wall junctions, door frames, floor interfaces, fasteners, and structural supports.

- Design vapour management: especially for refrigerated spaces (condensation risk at penetrations and junctions).

- Plan penetrations early: coordinate MEP routes to avoid late-stage cutting and patching.

- Quality checks on-site: joint sealing, continuity of air barrier, door alignment, and protective finishing in corrosive/coastal environments.

- Commission and monitor: validate temperatures, humidity, and energy consumption; fix leaks early and maintain seals over time.

Related Rinac resources

- Insulated Sandwich Panels: Applications, Advantages, and Innovations

- Prefabricated Buildings with Sandwich Panels

- PUF Panels: Comprehensive Guide

- Durability & Insulation Properties of Prefab Sandwich Panels

- RPUF vs PIR: Safety and Savings

Explore Rinac panel systems

FAQs

1) Do sandwich panels really reduce electricity bills in India?

Yes, especially in buildings with large roof/wall areas and long operating hours. Panels reduce conductive heat gain and, when properly sealed, can cut infiltration-driven loads. The magnitude depends on climate, ΔT, and how well joints and penetrations are detailed.

2) Which is better for energy efficiency: PIR or PUF panels?

Both are high-performance insulation materials. PIR is often chosen when a project wants strong thermal performance with improved fire behavior, while PUF/RPUF is widely used for robust insulation performance across cold chain and industrial buildings. The right choice depends on the project’s risk and compliance requirements.

3) What matters more: thickness or airtightness?

You need both. Extra thickness helps reduce conduction, but leaks at joints, doors, and penetrations can erase a significant portion of savings by increasing sensible and latent loads.

4) Are sandwich panels suitable for warm-humid or coastal cities?

Yes, but detailing is critical. Corrosion-resistant facings, proper sealing, and moisture/vapour control strategies help maintain long-term performance in humid and coastal conditions.

5) How do sandwich panels support compliance-focused projects (like ECBC-aligned buildings)?

They help deliver predictable envelope performance (lower U-values) and support high-quality installation outcomes. For ECBC applicability and exact targets, teams typically validate design against the applicable envelope requirements and compliance pathway.

6) What should I ask a vendor/contractor before finalizing panels?

Ask about core type and density, thickness options, joint system and sealing approach, fire performance evidence, corrosion protection, installation QA process, detailing support, and after-sales service for long-term upkeep.

Want a lower-energy building envelope without project delays?

Rinac designs and delivers clean modular construction and insulated panel-based building envelopes for cold chain, food processing, pharma, and industrial facilities across India.

Talk to our team

to shortlist the right panel system, thickness, and detailing strategy for your site conditions.