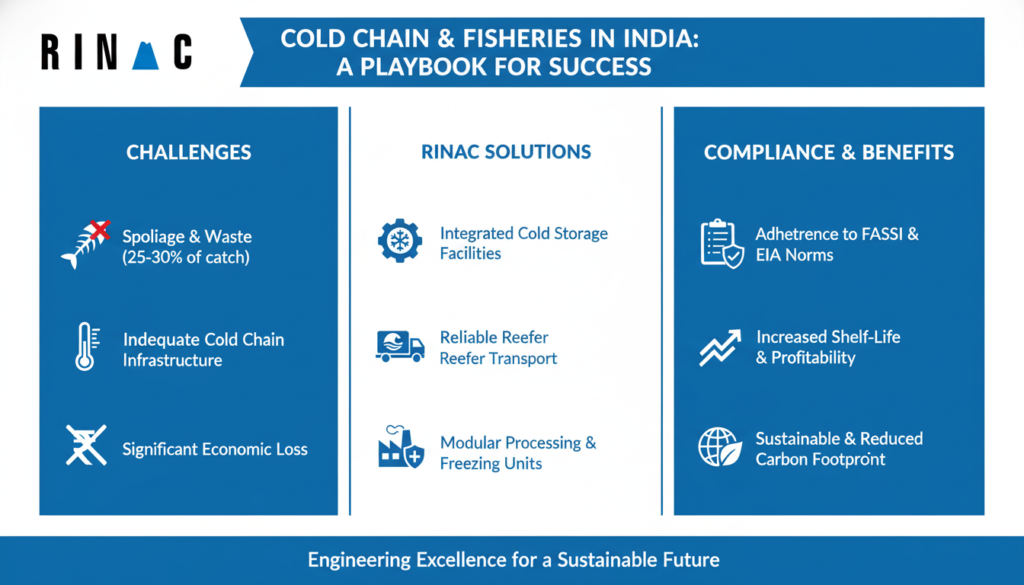

Cold Chain / Cold Storage for Fisheries in India: A Practical, Compliant Playbook (with Rinac Solutions)

Seafood is one of the most temperature-sensitive food categories on the planet. Minutes and degrees matter—because even small breaks in temperature control can accelerate spoilage and quality loss. Rinac’s fisheries cold chain work focuses on exactly that problem: protecting seafood quality from landing to processing to storage and distribution.

This guide is written for the Indian fisheries ecosystem—landing centers, traders, processors, cold stores, exporters, and retail distributors—where high ambient temperatures, humidity/monsoon conditions, coastal corrosion, and power/logistics variability make cold chain execution uniquely challenging. Rinac explicitly calls out these real-world challenges—temperature uniformity, humidity control, rapid cooling, corrosion & hygiene, odour control/cross-contamination, and energy efficiency—as core design problems to solve in seafood cold storage.

1) The “non-negotiables” of seafood cold chain

Temperature targets (common reference points)

While your exact targets depend on species, product form (fresh/chilled/frozen/value-added), and customer/regulatory requirements, the following references are widely used in global codes and Indian standards:

- Chilled seafood: Codex notes chilled products should be held around 0°C (as close to 0°C as possible) and references chill room conditions in the 0 to +4°C range.

- Frozen seafood: Codex states frozen fish and shellfish should be maintained at -18°C or colder.

- India (FSSAI) – quick frozen fish: FSSAI standards specify quick frozen fish “shall be stored at -18°C or lower” and the label should indicate “Keep Frozen at -18°C or below.”

Why this matters: Rinac highlights that consistent temperature control helps prevent spoilage and bacterial growth and protects product quality through the chain.

Practical note (India-specific): If you operate across multiple states/customers, align your SOPs to the strictest applicable requirement (often export/customer specs), then enforce through monitoring + audit-ready records.

2) What makes fisheries cold chain harder in India (and what to design for)

Rinac’s fisheries page is clear about the real operational pain points you must engineer around:

- High humidity + frequent door openings → frost/ice formation, freezer burn risk, unstable temperatures

- Rapid chilling/freezing needs → quality retention depends on fast pull-down and uniformity

- Salt + coastal environments → corrosion-resistant materials and hygiene-first design

- Odour + cross-contamination → zoning, segregation, airflow planning, and cleaning SOPs

- Energy efficiency constraints → insulation, right-sizing, racking layout, and maintenance strategy

Rinac also describes a typical seafood facility requirement spanning multiple zones—from process areas, to chilled storage, to blast freezing, to finished goods storage—and even lists example ranges it supports, including chilled storage around 2°C, blast freezing down to -40°C, and storage around -25°C (project-dependent).

3) The fisheries cold chain: stage-by-stage blueprint (landing → consumer)

Stage A: Landing center / first-mile handling

Goal: start cooling immediately; reduce time at ambient.

What good looks like:

- Rapid icing / chilling at landing to slow down deterioration (Codex emphasizes chilling should begin as soon as possible and chilled products should be kept near 0°C).

- Hygienic handling + cleanable surfaces (important in India where wet handling is common)

Rinac-fit solutions

- Ice Machines (flake/tube) + brine chillers for reliable ice supply near the source. Rinac’s ice machines include flake and tube options and describes corrosion-friendly materials (e.g., stainless steel components) and operational design ranges across ambient conditions.

- On Rinac’s fisheries page, the ice-type guidance is also practical: flake ice is positioned as suitable for direct contact with fish, while block ice is used for long-distance transport scenarios.

Stage B: Pre-processing and grading

Goal: keep product cold while sorting, washing, packing.

Design moves:

- A temperature-controlled process zone (not a hot hall with “ice as a workaround”)

- Drainage + hygienic wall/floor finishes; corrosion resistance for coastal plants

Rinac-fit solutions

- Rinac references process-area needs as part of overall seafood facility temperature zoning.

- For modular/clean build environments, Rinac also positions itself as a builder of cold-chain infrastructure and modular construction on its product pages.

Stage C: Freezing (blast / IQF / brine)

Goal: freeze fast and uniformly (quality + safety + shelf life).

Two common paths:

- Blast freezing for bulk loads or trays

- IQF for pieces (shrimp, fillets, value-added items) to prevent clumping and preserve texture

Rinac-fit solutions

- Blast Chillers & Freezers: Rinac lists rapid chilling/freezing capabilities and references typical operating targets (e.g., core temperature targets and fast chilling cycles) for food safety and quality preservation.

- IQF Systems: Rinac describes IQF as rapid freezing of individual items, with designs such as straight-line and spiral configurations, plus hygienic construction and energy-conscious components.

- IQF on Rinac is also tied to its Freezoline brand positioning for food preservation across storage/processing/transport.

Stage D: Cold storage (chilled / frozen)

Goal: hold product at spec with minimal fluctuations and strong hygiene.

Chilled storage

- Codex references chilled holding around 0°C (as close as possible), with chill room conditions in the 0–4°C range.

Frozen storage

- Codex guidance: -18°C or colder.

- FSSAI quick frozen fish: store at -18°C or lower + label accordingly.

Rinac-fit solutions

- LiteCold Modular Cold Rooms: Rinac describes LiteCold as modular, customizable cold rooms designed for 35–45°C ambient conditions, with microprocessor temperature control and use cases spanning +4°C chilled to -18°C frozen.

- PreServa 3200L Compact: positioned as a compact modular step-in chiller/freezer for high ambient conditions, with cleanable design and microprocessor controls.

- MRW Series Walk-in Cold Rooms: Rinac emphasizes modularity, fast installation, microprocessor-based control, and operation engineered for 38°C to 46°C ambient conditions—highly relevant in many Indian coastal and inland markets.

Stage E: Cold logistics (mid-mile + last-mile)

Goal: maintain temperatures during transport—especially in hot weather and traffic.

Rinac-fit solutions

- Refrigerated Containers for Vehicles (Chillkart): Rinac describes Chillkart as eutectic-plate based refrigerated units designed to maintain temperature during transport (including last-mile use cases), with insulated containers fitted to trucks/vans.

- Practical India use case: pre-charge eutectic plates at the hub, then run routes without active refrigeration running continuously (especially useful for urban last-mile and distribution density).

Stage F: Warehousing layout and throughput

Even a great cold room underperforms if pallet flow is chaotic or access is slow.

Rinac-fit solutions

- StorEdge & Constructor (Storage & Racking): Rinac offers pallet racking and mezzanine systems under StorEdge and Constructor, explicitly framed for multi-commodity warehouses and cold chain. It also notes suitability across a wide temperature range and alignment to EN 15512 for modular racking systems.

4) Three India-ready cold chain “reference designs” using Rinac building blocks

1) Landing center / trader hub (micro cold chain)

Best for: harbours, fish markets, aggregators

- Ice + insulated handling + compact cold room (LiteCold / PreServa)

- Chilled dispatch with last-mile containers where needed (Chillkart)

2) Processor / exporter (multi-zone facility)

Best for: shrimp processors, fillet/value-added plants

- Controlled process zones + blast freezing / IQF lines

- Frozen storage at -18°C or colder per Codex/FSSAI references

- High-density racking for throughput and auditability

3) Domestic distribution + retail supply

Best for: state-wide distributors, QSR supply chains

- Multi-temperature warehousing (MRW/LiteCold rooms)

- Route execution with insulated vehicle containers (Chillkart)

5) Monitoring, serviceability, and uptime (where projects succeed or fail)

A fisheries cold chain isn’t just a build—it’s a long-term operational discipline. Rinac explicitly references IoT-enabled monitoring for temperature/humidity/machine health and after-sales constructs such as AMC, calibration, audits, and energy optimization for marine cold chain applications.

This matters in India because:

- peak season loads stress equipment

- power/voltage swings happen

- hygiene expectations (and audits) are rising

6) Procurement checklist (India-focused, practical)

Use this when scoping a fisheries cold chain project:

- Product & process definition

- Species, form (whole/fillet/IQF/value-added), target markets (domestic/export), packaging type

- Temperature map

- Define zones (process → chilled → blast/IQF → frozen storage) consistent with common chilled and frozen references (Codex/FSSAI).

- Ambient & site conditions

- Coastal corrosion risk (material selection)

- High ambient (consider equipment designed for high ambient ranges—LiteCold 35–45°C; MRW 38–46°C).

- Throughput & layout

- Receiving/dispatch bays, staging areas, racking plan (StorEdge/Constructor)

- Hygiene design

- Washable surfaces, drainage, odour/cross-contamination controls

- Transport strategy

- Mid-mile reefer vs eutectic last-mile containers (Chillkart)

- Monitoring & service

- Logging, alarms, calibration and service plan

FAQs (ready to publish)

1) What temperatures should seafood be stored at in India?

For frozen products, Codex references -18°C or colder, and FSSAI’s quick frozen fish standard references storage at -18°C or lower with label guidance. Chilled products are commonly held close to 0°C (Codex) with chill room conditions typically in the 0–4°C range.

2) What are the biggest cold storage challenges for seafood?

Rinac lists temperature uniformity, humidity management, rapid cooling/blast freezing needs, corrosion & hygiene, odour/cross-contamination, and energy efficiency as key challenges in seafood cold storage.

3) Which Rinac cold room is better for fisheries—LiteCold, PreServa, or MRW?

It depends on scale and workflow: LiteCold is positioned for modular cold storage across +4°C chilled and -18°C frozen use cases; PreServa targets compact step-in needs; MRW emphasizes scalable walk-in rooms designed for high ambient conditions and modular expansion.

4) When should a processor consider IQF?

If you sell shrimp, pieces, fillets, or value-added formats where “individual pieces” matter, IQF helps prevent clumping and supports easier portioning/packaging. Rinac describes IQF systems with straight-line or spiral configurations and hygienic, energy-conscious construction.

5) What type of ice is typically used for fish handling?

Rinac’s fisheries guidance distinguishes ice types—flake ice for direct contact with fish to maintain freshness, and block ice for longer-distance seafood transportation.

6) Can Rinac support monitoring and after-sales for marine cold chain sites?

Rinac states it offers IoT-enabled monitoring and AMC/service support including calibration, audits, and performance optimization—useful for maintaining uptime in seafood operations.