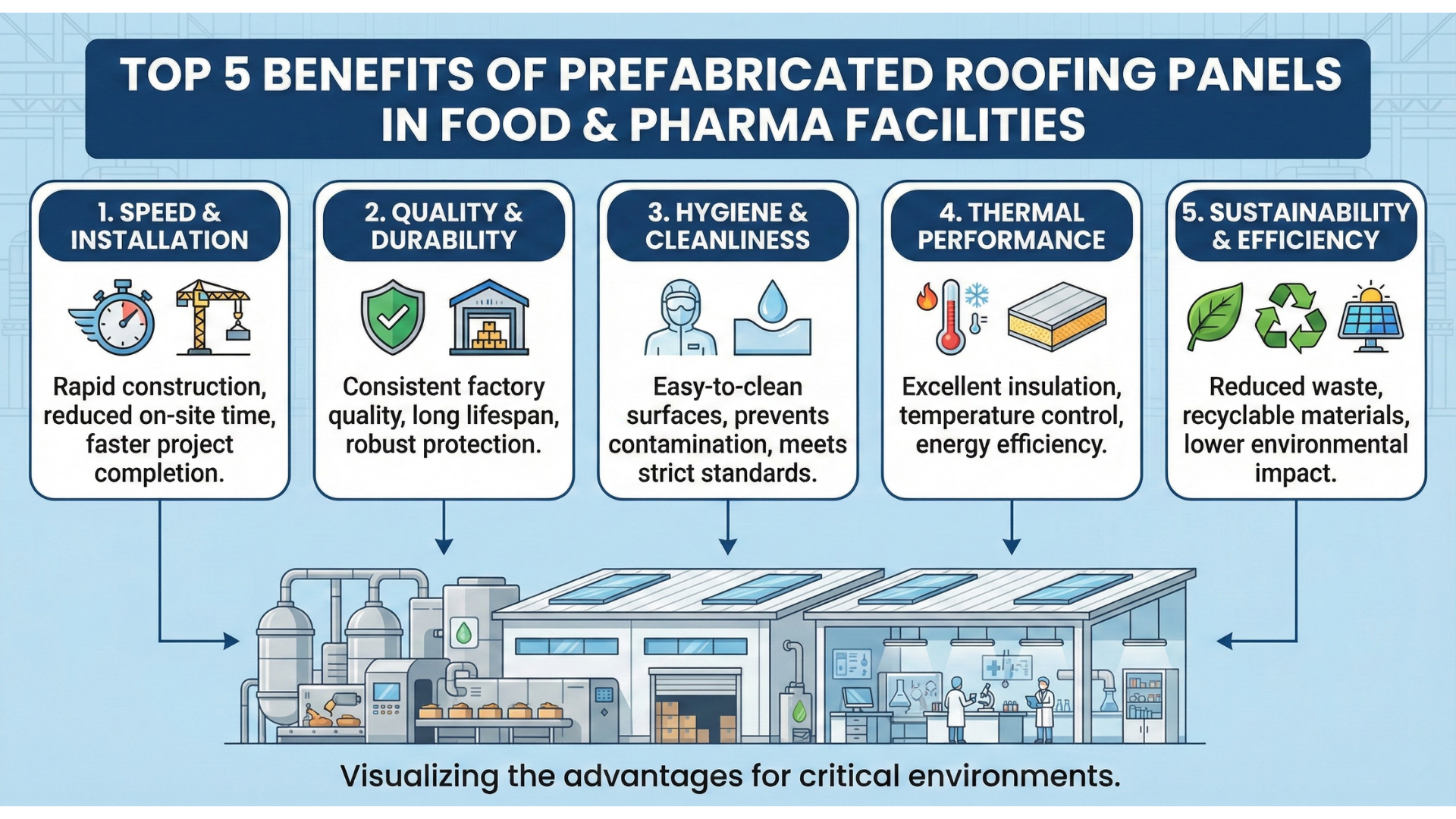

Top 5 Benefits of Prefabricated Roofing Panels in Food & Pharma Facilities

TL;DR

Food and pharma facilities cannot treat the roof like “just a shed cover.” The building envelope directly impacts

hygiene, temperature stability, humidity/condensation risk, pest control, and compliance readiness.

Prefabricated insulated roofing panels (often called sandwich roof panels) help teams achieve a cleaner, tighter,

better-insulated envelope with faster installation and more consistent performance, especially when paired with

modular wall/ceiling systems used in controlled environments.

- Cleaner envelope: smooth, sealed interior surfaces are easier to keep hygienic and inspection-ready.

- Lower heat load: insulation reduces heat flow, stabilizing HVAC and process conditions.

- Less condensation risk: better air/vapor control reduces drip and microbial risk in sensitive zones.

- Speed + predictability: off-site manufacturing improves consistency and can shorten project timelines.

- Risk & lifecycle value: better safety options (including fire-oriented specifications) and durability planning.

Why Roofing Matters in Food & Pharma

In regulated environments, facility design is part of product protection. Regulations and guidance commonly emphasize

hygienic premises, cleanable surfaces, and construction that supports sanitary operations and contamination control.

For example, food hygiene frameworks (FSMS/GHP/GMP) and pharmaceutical GMP guidance repeatedly highlight the need for

buildings and surfaces that can be cleaned, maintained, and operated without creating contamination risk.

The roof is a major “control surface” because it influences:

- Temperature stability: heat ingress drives HVAC load and can increase temperature excursions.

- Humidity and condensation: uncontrolled vapor + thermal bridges can create drips and microbial risk.

- Cleanability and particle control: surfaces above processing/packing zones should not shed particulate.

- Pest pathways and leakage: gaps and unsealed joints can become entry points or dirt traps.

- Fire and resilience: insurers, auditors, and EHS teams often require documented, risk-reducing assemblies.

Top 5 Benefits of Prefabricated Roofing Panels

1) Hygiene-ready surfaces that support GMP, FSMS, and cleanroom discipline

In food and pharma, the “inside face” of the roof/ceiling area matters as much as the outside weathering layer.

Guidance for pharmaceutical manufacturing areas often calls for interior surfaces (including ceilings) to be smooth,

free from cracks/open joints, non-shedding, and easy to clean or disinfect. Similarly, food hygiene frameworks expect

premises that can be maintained in sanitary condition.

How prefabricated panels help: Factory-made panels can deliver consistent, smooth liners, controlled joint

geometry, and fewer uncontrolled site-fabricated interfaces. That makes it easier to design for:

- Cleanable surfaces and fewer dust-traps

- Sealed junctions at penetrations (lights, HVAC, sprinklers, cable trays)

- Reduced particulate shedding from degraded finishes

- More predictable detailing for validation/qualification documentation

Practical note for pharma/clean zones: Many cleanroom-focused guidelines emphasize that ceilings should be

designed and sealed to prevent contamination from the void above. Using panelized roof/ceiling systems can simplify

sealed detailing when compared to multi-layer, site-built assemblies.

Where Rinac fits: For roof and envelope systems used in controlled environments, explore

InstaRoof insulated roofing panels,

InstaCeil ceiling panels, and

InstaWall insulated wall/partition panels.

For modular construction systems used in clean, insulated structures, see

InstaBuild.

2) Thermal performance that stabilizes process, storage, and utility loads

Insulation reduces heat flow across the building envelope. In facilities where temperature consistency matters

(processing, packing, warehousing, cold rooms, and temperature-sensitive staging), a better-insulated roof helps

reduce heat ingress and can lower HVAC or refrigeration load.

How prefabricated insulated roof panels help:

- Continuous insulation layer: fewer weak points compared to piecemeal insulation installation.

- Faster “thermal close-out”: reaching stable indoor conditions earlier in the project timeline.

- Better occupant comfort: reduced radiant heat and hotspots in high-occupancy work zones.

Where Rinac fits: Rinac roofing systems like

InstaRoof (available in 30mm and 50mm options with PUF or PIR cores)

and CoolTop are designed for insulated roofing applications where reducing

heat load and supporting controlled conditions are priorities.

Important: Actual energy impact depends on thickness, detailing, air-sealing, climate, internal loads,

and ventilation strategy. For regulated environments, consider documenting assumptions through envelope calculations

and commissioning/qualification plans.

3) Condensation and moisture-risk control to reduce spoilage, corrosion, and mold

Condensation is not just a comfort issue in food and pharma. It can become a direct contamination hazard if moisture

drips onto product zones or packaging lines, and it can accelerate corrosion and microbial growth in hidden voids.

Building-envelope guidance consistently stresses controlling air leakage and vapor movement to manage moisture risk.

How prefabricated roof panels help:

- Tighter joints: Interlocking panel profiles and planned sealant strategy can reduce uncontrolled air leakage.

- Fewer voids: Less “mystery space” where moisture can accumulate unseen.

- Cleaner penetrations: Standardized, repeatable flashing and curb details reduce leak/condensation points.

Food + cold-chain reality: Facilities often have high humidity zones (washdown rooms, spiral freezers,

chilled docks) sitting next to warmer ambient spaces. That makes condensation control primarily a design problem,

not a housekeeping problem. Panel systems can simplify a continuous envelope when the detailing is done correctly.

Where Rinac fits: If you are building insulated rooms or controlled zones, pairing roof panels with

InstaBuild modular panel systems and

InstaWall can help create a continuous envelope across roof, wall,

and ceiling junctions.

4) Faster installation and predictable quality (less downtime, fewer site variables)

Food and pharma expansions are often time-sensitive because downtime is expensive and qualification timelines can be

unforgiving. Prefabricated systems reduce on-site variability: the panels arrive made-to-spec, and the “work on site”

is focused on assembly and detailing instead of fabrication.

Industry research on modular/off-site construction notes that modular approaches can accelerate timelines significantly

when planned and executed well. For operating plants, that speed is not just a project KPI; it is a business continuity

advantage.

Where speed matters most:

- Brownfield retrofits: installing envelope upgrades while maintaining operations

- Fast-track cold-chain expansions: additional insulated bays, staging rooms, or controlled packing lines

- Quality-driven builds: fewer rework cycles due to more repeatable assembly

Where Rinac fits: Rinac’s

InstaBuild is positioned as a prefabricated sandwich panel system for

fast assembly of cold rooms, clean rooms, and insulated structures. You can also review Rinac’s broader work via the

Projects page.

5) Safety, risk management, and lifecycle durability

Safety and resilience requirements show up in multiple places: EHS expectations, insurer requirements, customer audits,

and local building/fire rules. Roof systems must manage wind uplift, fire risk, penetrations (HVAC, vents, PV), and

long-term maintenance access without degrading hygienic conditions inside.

How prefabricated panel systems help:

- Documented assemblies: clearer specification of tested/approved roof system configurations.

- Better maintenance planning: defined access/repair approach reduces ad-hoc patchwork.

- Lifecycle clarity: planned seal replacement cycles and corrosion protection strategy.

Fire + risk note: If your project or insurer asks for FM-oriented guidance or tested roof system design,

review FM resources and align the assembly specification accordingly. Choosing a fire-oriented core (for example, PIR)

and tested/approved assemblies may be part of risk strategy depending on your facility and hazard analysis.

Where Rinac fits: Rinac offers insulated roofing options including PIR (fire-rated) core variants on

InstaRoof. For clean modular construction approaches, explore

HPCC and the modular/cleanroom discussion in

this Rinac blog.

Spec Checklist: What to Ask For (Food & Pharma Roofing Panels)

Use this checklist to reduce redesign and audit surprises:

A) Hygiene & Cleanability

- Interior liner finish appropriate for your cleaning regime (washdown, disinfectants, frequency)

- Joint detailing that avoids open gaps and dirt traps; sealed and inspectable junctions

- Penetration strategy: standardized curbs/flashings for HVAC, vents, pipes, cable trays, sprinklers, lights

- Where relevant: sealed ceiling concept to reduce contamination risk from voids above

B) Thermal & Moisture Control

- Panel thickness and insulation type aligned to your setpoints and climate

- Air barrier and vapor control strategy (especially critical where cold rooms meet ambient spaces)

- Thermal bridge review at purlins, fasteners, and junctions

- Condensation risk review for high-humidity zones and defrost cycles

C) Safety & Compliance Readiness

- Roof assembly approach for wind resistance and drainage; slope, gutters, and maintenance walk paths

- Fire-risk requirements (EHS/insurer/customer): core choice and assembly documentation

- Commissioning and qualification plan alignment (IQ/OQ/PQ where applicable)

D) Operations & Lifecycle

- Access strategy for maintenance without damaging hygienic interiors

- Sealant inspection/replacement plan (planned maintenance beats emergency patching)

- After-sales support expectations (response SLAs, spares, service coverage)

How Rinac Helps: Roofing + Clean Modular Construction

Rinac’s portfolio is relevant when your priority is a controlled, insulated envelope delivered with speed and repeatability.

Depending on your zone classification and operating conditions, teams commonly combine roofing, ceiling, and wall panel systems

to maintain a continuous envelope.

Relevant Rinac links

- InstaRoof insulated roofing panels

- CoolTop roofing

- InstaCeil ceiling panels

- InstaWall insulated wall/partition panels

- InstaBuild prefabricated sandwich panel systems

- HPCC (clean modular construction)

- Projects

- After-sales service

- Contact Rinac

Tip: If you are planning a food/pharma build or retrofit, align early with QA/Validation and EHS so roof,

ceiling, HVAC penetrations, and cleaning protocol work together. The best panel system still fails if the detailing is not

designed for your cleaning, humidity, and maintenance reality.

FAQs

Are prefabricated roofing panels acceptable for GMP or food safety audits?

Panels can support compliance when the overall facility design enables sanitary operation and contamination control,

including cleanable surfaces and sealed detailing. Audit success depends on the complete envelope design, installation

quality, and documented maintenance/cleaning program, not the panel alone.

PUF vs PIR: which is better for food & pharma roofing?

Both are used in insulated panels. PIR is often selected when projects prioritize enhanced fire performance characteristics

as part of a risk strategy. The right choice depends on your hazard analysis, insurer requirements, process temperatures,

and facility design.

How do roofing panels reduce condensation risk?

Condensation is controlled by managing temperature gradients, air leakage, and vapor movement. Panel systems can help by

creating a more continuous insulated envelope with fewer uncontrolled gaps, but the design must include correct vapor/air

barrier placement and well-detailed penetrations.

Can these panels work with cleanroom or controlled packing zones?

Yes, especially when paired with ceiling/wall panel systems and properly sealed junctions. Many cleanroom guidance documents

emphasize sealed ceilings and cleanable surfaces to reduce contamination risk from voids above.

What is the biggest mistake teams make with panel roofs in regulated facilities?

Treating penetrations and junctions as an afterthought. If curbs, flashings, and seals are improvised on site, you can end up

with leaks, microbial harborage points, and recurring maintenance failures.

What should we prepare for qualification/validation?

Typically: envelope drawings, penetration schedules, cleaning SOP alignment, material/finish documentation, and an inspection

plan for seals and junctions. Your QA/Validation approach (IQ/OQ/PQ) will vary by facility type and regulatory expectations.